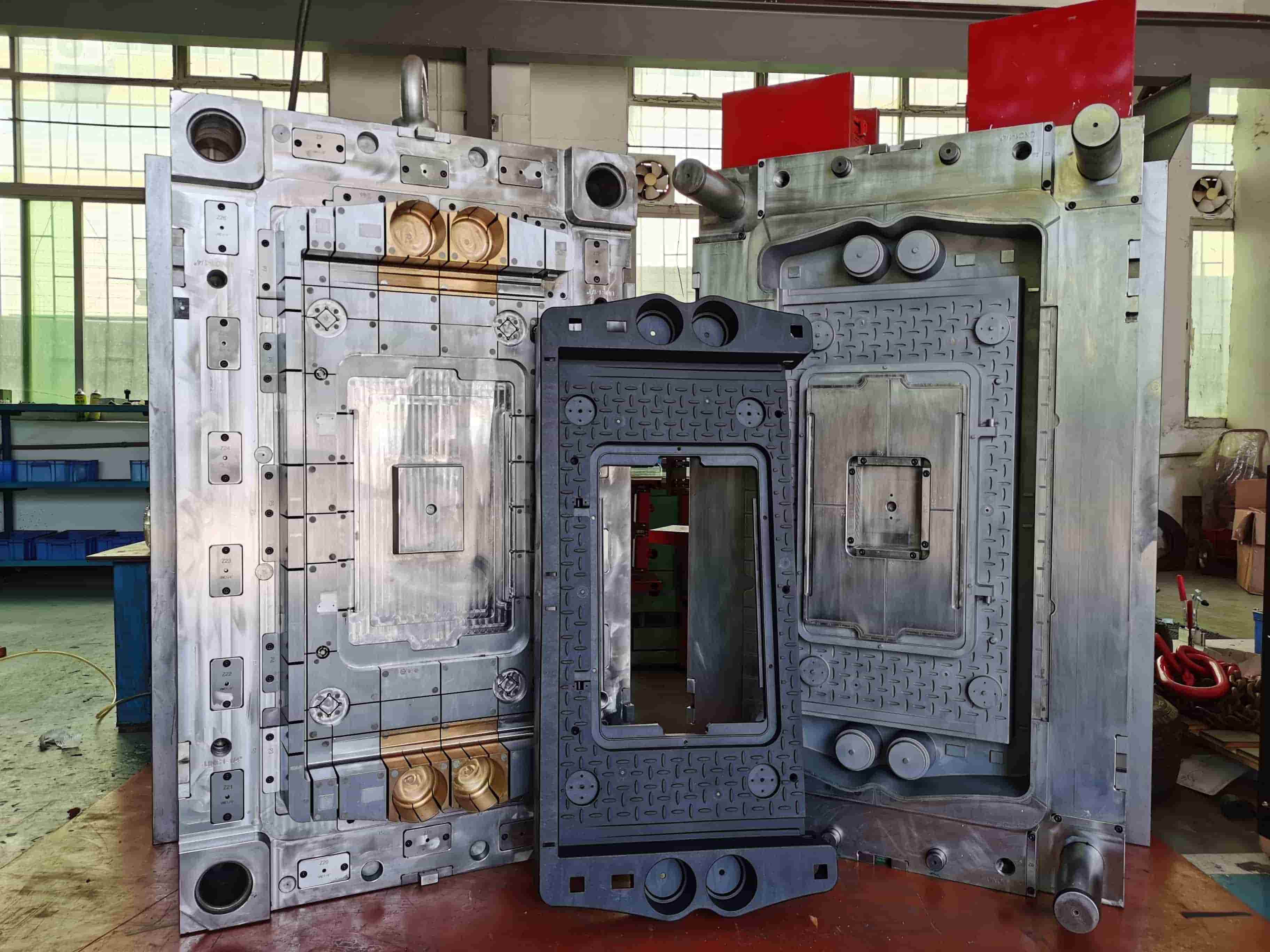

5 Uhlobo lwesikhunta somjovo olusekelwe kuzinga le-US SP1-SPE

Uma udinga ukuthuthukisa umkhiqizo noma iphrojekthi, imishini yehadiwe iyisithwali esingenakugwenywa, futhi ama-casings epulasitiki athandwa kakhulu njengamanje.Ukukhiqizwa kwamagobolondo epulasitiki kufanele kuhlukaniseke ekubunjweni komjovo.Njengomkhiqizi nomnikezeli wesikhunta somjovo waseShayina, sineminyaka engaphezu kwe-10 yesipiliyoni sokuthumela ngaphandle futhi siyazazi izidingo zesikhunta zamakhasimende emazweni ahlukene.Namuhla sizokhuluma ngokuthi yiziphi izigaba zokubumba ze-US SP1-SPE standard, futhi ngithemba ukuthi kuzoba usizo kuwe.

1. Isikhunta se-Class 101 (SP1-SPE standard 1,000,000 ubhiya noma ngaphezulu, isikhunta sokukhiqiza ukunemba kwesikhathi eside)

1).Imidwebo enemininingwane yesakhiwo sesikhunta iyadingeka;

2).Ubulukhuni obuncane bezinto ezingenalutho zesikhunta ngu-28HB (DME #2 steel/king material electroplating nickel/P20 electroplating Nickel);

3).Insimbi yemojula yangaphakathi eneglue kufanele iqiniswe ibe yi-48~52HRC, nezinye izingxenye ezifana nezikhundla zemigqa, izingidi zokucindezela, ubuhlalu, njll. kufanele futhi kube yi-hardware;

4).Ipuleti le-ejector kufanele libe nezigxobo zomhlahlandlela;

5).Imigqa

6).Uma kunesidingo, isikhunta esiphezulu, isikhunta esiphansi kanye nendawo yomugqa kufanele kube nokulawula izinga lokushisa;

7).Kuzo zonke iziteshi zamanzi, kunconywa ukusebenzisa i-electroless nickel dipping noma i-420 insimbi engagqwali njengesifanekiso, esingavimbela ukugqwala futhi sihlanze udoti;

8).Ilokhi eqondile noma i-oblique lock iyadingeka.

2. Thayipha isikhunta esingu-102 (ubhiya ongekho ngaphezu kwe-1,000,000, ukukhiqizwa kwesikhunta ngobuningi)

1).Kudingeka umdwebo onemininingwane wesakhiwo sesikhunta;

2).Ubulukhuni obuncane be-mold base material yi-165BHN (DME #2 steel/AISI1050);

3).Amamojula angaphakathi anezikhundla zeglue Insimbi kufanele iqiniswe ibe ubuncane be-48 ~ 52HRC, nezinye izingxenye eziwusizo kufanele ziphathwe ngendlela efanayo;

4).Kunconywa ukusebenzisa izingidi eziqondile noma izingidi ze-oblique;

5).Izinto ezilandelayo zingadingeka noma zingadingeki, kuye ngenani lokugcina lokukhiqiza.Kunconywa ukucaphuna Lapho usebenzisa izinto ezilandelayo, hlola ukuthi kudingekile yini: A. I-Ejector plate guide post, B. Row position hard sheet, C. Electroplating umgodi wokuletha amanzi, D. Electroplating mold cavity.

3. Thayipha isikhunta esingu-103 (ubhiya obungaphansi kuka-500,000, isikhunta sokukhiqiza sevolumu ephakathi)

1).Kudingeka umdwebo onemininingwane yesakhiwo sesikhunta;

2).Ubulukhuni obuncane be-mold base material yi-165BHN (i-DME #1 steel/1040 steel/S50C);

3).Izinto zensimbi zesikhunta sangaphakathi yi-P20 (28 ~ 32HRC) noma ukuqina okuphezulu (36 ~ 38HRC);

4).Ezinye izidingo zincike ezidingweni.

4. Thayipha isikhunta esiyi-104 (ubhiya obungaphansi kuka-100,000, isikhunta esincane sokukhiqiza)

1).Kudingeka umdwebo onemininingwane wesakhiwo sesikhunta;

2).Insimbi emnene noma i-aluminium (insimbi engu-1040) ingasetshenziselwa isisekelo se-mold material P20 (28~32HRC);

3).Isikhunta sangaphakathi singasetshenziswa i-Aluminium, insimbi emnene noma ezinye izinsimbi ezivunyiwe;

4).Ezinye izidingo zincike ezidingweni.

5. Thayipha isikhunta esiyi-105 (ubhiya obungaphansi kwama-500, isikhunta sokuqala noma isikhunta sokuhlola)

I-aluminium casting noma i-epoxy resin nanoma iyiphi into ingasetshenziswa inqobo nje uma inamandla anele ukukhiqiza inani elincane lokuhlola.

Isikhathi sokuthumela: Jul-10-2023