I-Aluminium die casting iyinqubo lapho ingxubevange ye-aluminium encibilikisiwe iphoqelelwa ibe yinsimbi yensimbi noma isikhunta ngaphansi kwengcindezi.Ngokuvamile isetshenziselwa ukukhiqiza ngobuningi futhi ingakhiqiza izingxenye ezinemininingwane eyinkimbinkimbi kakhulu kanye nezingxenye ezinokubekezelelana okuqinile kakhulu ngezindleko eziphansi.Izingxenye ezikhiqizwe nge-aluminium die casting zinezakhiwo ezinhle kakhulu zemishini futhi zimelana nokugqwala, ukushisa, nokuguga.

• I-Aluminium die Casting inikezela ngenani lezinzuzo, ezinye zazo ezihlanganisa:

• Izingxenye ezingasindi neziqinile ezibiza kakhulu kunezinye izinhlobo zezinsimbi

• Ukusebenza okuthuthukisiwe ngenxa yezikhathi zokuhola ezimfishane kanye nokuncipha kwemfucuza

• Ukwanda kwenkululeko yokuklama ngenxa yokungabi lula kwayo, okuvumela izimo eziyinkimbinkimbi ukuthi zidalwe ngokushesha futhi kalula

• Ukumelana nokugqwala, ukushisa, nokuguga uma kuqhathaniswa nezinye izinsimbi

• Ikhono lokukhiqiza ngobuningi, nama-alloys amaningi e-aluminium akwazi ukumelana nokucindezela okukhulu namazinga okushisa

I-aluminium die casting iyindlela yokukhiqiza enemisebenzi eminingi esetshenziswa ukukhiqiza izingxenye eziningi zezimboni ezahlukahlukene.Kusukela ezingxenyeni zezimoto kuya ekufakweni kwezokwelapha nokunye okwengeziwe, i-aluminium die casting ingasetshenziswa ukudala cishe noma yini, njengokuthi:

• Imboni yezimoto:Izingxenye ezihlukahlukene ezihlanganisa ukunquma kwangaphakathi, ama-transmission casings, amabhulokhi enjini nezikhwezi, ama-radiator, namasistimu wokushaja.

• Imboni ye-Aerospace:Izingxenye eziyinkimbinkimbi njengamaphampu, izinzwa, ama-actuator, imibhoshongo yomsakazo nezimpondo.

• Imboni yezokwelapha:Izingxenye ezikhetheke kakhulu njengamavalvu enhliziyo afakelwayo, amathuluzi okuhlinza, ama-orthotics nama-prosthetics.

• Izinto zasendlini:Amahinge namalashi weziqandisi nemishini yokuwasha kanye nezinye izinto ezincane ezidinga umsebenzi wemininingwane eyinkimbinkimbi.

• njll,.

Ukukhetha ingxubevange ye-aluminium efanele yephrojekthi yakho yokusakaza ngefa kubalulekile ukuze uqinisekise ukuthi umkhiqizo wakho osuphelile uhlangabezana nakho konke okucacisile.Nawa amanye amathiphu ekukhetheni ingxubevange efanele:

• Cabangela izimfuneko zamandla nokuqina kwengxenye yakho.Ama-alloys ahlukene anikezela ngamazinga ahlukahlukene wamandla nokumelana nokuguga, ngakho-ke kubalulekile ukukhetha ingxubevange ezohlangabezana nezidingo zohlelo lwakho lokusebenza.

• Hlola izinga elidingekayo lokumelana nokugqwala.Ama-alloys e-aluminium angelashwa futhi afakwe i-anodized ukuze anikeze ukuvikeleka okwengeziwe ekugqwaleni, ngakho-ke qiniseka ukuthi ucabangela ukuthi iyiphi imvelo izingxenye zakho ezizodinga ukubekezelela.

• Cabangela izindleko zokukhiqiza nezikhathi zokulethwa.Ngokuya ngobunkimbinkimbi bengxenye, ama-alloy ahlukene angase adinge izindlela zokukhiqiza ezihlukene noma ukutshalwa kwezimali kwamathuluzi, ngakho-ke kubalulekile ukukala lezi zici lapho ukhetha ingxubevange yephrojekthi yakho.

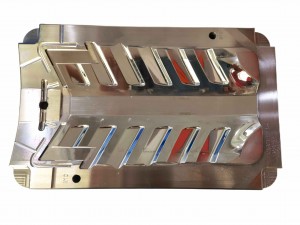

Izidingo zamathuluzi nemishini yokufaka ukufa kwe-aluminium ziyahlukahluka kuye ngengxubevange esetshenzisiwe, ukuba yinkimbinkimbi kwengxenye, nezinye izici.Ngokuvamile, kubalulekile ukucabangela lokhu okulandelayo lapho ukhetha uhlobo lwethuluzi:

• Ukukhethwa kwempahla yamathuluzi kufanele kusekelwe kungxubevange esetshenziswayo kanye namazinga okushisa adingekayo ukuze kukhiqizwe imiphumela yekhwalithi.Ngokuvamile sisebenzisa i-H13, SKD61, 8407, 8418, 8433 kanye ne-W360 kumathuluzi e-die cast.

• Kufanele kuqashelwe ukuze kuqinisekiswe ukuthi kune-engeli yokusalungiswa eyanele ukuze izingxenye zikwazi ukuqhela kalula efayini lapho zikhishwa.Ukuhlaziywa okuphelele kwe-DFM kufanele kwenziwe ngaphambi kokwakhiwa kwesikhunta.

• Umshini wesibili ungase udingeke ngemva kokulingisa ukuze kuzuzwe izimo ezithile noma imininingwane, kuhlanganisa umshini we-CNC, ukubhoboza, ukucofa nokunye.

• Izinketho zokuqeda indawo engaphezulu njengokuqhunyiswa kwesihlabathi noma ukupholisha okudlidlizayo, ukugcotshwa kwe-anodizing, ukucwenga noma ukupenda kungase kudingeke kuye ngezidingo zakho.

I-CNC Ilungiselela Izingxenye Ezisikiwe

Ukuxazulula izinkinga ezivamile ku-aluminium die castings kungaba inqubo edla isikhathi futhi ebizayo, kodwa kubalulekile ukuze uqinisekise ikhwalithi yezingxenye zakho.Nawa amanye amathiphu okuxazulula izinkinga ezivamile ngokusakazwa kwe-aluminium die:

• I-Porosity:Hlola ingxenye yakho ukuze uthole noma yimaphi amaphinifa noma ezinye izindawo ezingaholela ku-porosity.Uma uthola noma yikuphi, qiniseka ukuthi ubuyekeza izinga lokushisa lesikhunta, ingcindezi yomjovo kanye nezinye izici okungenzeka ziye zathinta ukugcwaliswa kocezu.

• Ukuhlanekezela:Uma uthola ukuhlanekezela ezingxenyeni ngemva kokuthi zikhishiwe ku-diyizi, hlola ukuze ubone ukuthi umklamo wesikhunta noma izikhathi zokupholisa kungenzeka yini zibangele le nkinga.Ungase udinge ukulungisa lezi zilungiselelo ukuze uqalise ukukhiqiza esikhathini esizayo ukuze unciphise noma yikuphi ukuhlanekezela.

• Ukonakala kwendawo:Uma uhlangabezana nanoma ikuphi ukonakala okufana nama-splay marks noma amaphiko, hlola ukuthi ingabe kukhona ukungafani phakathi kwejubane lomjovo kanye nezinga lokuncibilika lokuncibilika, njengoba lokhu ngokuvamile kungabangela lezi zinkinga.Kungase futhi kudingeke ukulungisa amapharamitha okusakaza afana namazinga okushisa namazinga okupholisa ukuze kuncishiswe ukungapheleli kwendawo.

Lapho iphrojekthi entsha iqala, izingxenye ze-prototyping ezisheshayo ziyadingeka ezinhlotsheni zokuhlola.Kunezindlela eziningi zokwenza ama-prototypes afaka i-CNC machining, i-Vacuum Casting, ukuphrinta kwe-3D kanye ne-Rapid prototype tooling.

• Imishini ye-CNC ingenza izingxenye zensimbi nezepulasitiki nganoma yiliphi inani.

• I-Vacuum Casting eyezingxenye zepulasitiki ezingamayunithi angu-5-100 ngokusebenzisa isikhunta se-silicon

• I-3D Printing iwukuphrinta i-ABS, i-PA noma izingxenye zensimbi.Okwepulasitiki, izingxenye eziphrintiwe ze-3D azikwazi ukumelana nezinga lokushisa eliphezulu.

• I-Rapid prototype tooling isikhunta esithambile esenziwe ngensimbi ethambile efana ne-S50C noma i-Aluminium.Lesi sixazululo singakhiqiza izingxenye eziningi kune-Vacuum Casting.Isikhathi sokuhola sifushane kunethuluzi lokukhiqiza futhi intengo iphansi nayo.

Izinto esizisebenzisile: Ipulasitiki efana nePC, PMMA, POM, PP njll,.Insimbi njengensimbi, i-aluminium, ithusi, ithusi nokunye.

Indlela yokwenza izingxenye ze-silicon

Ukwakha ingxenye ye-silicone, uzodinga ukusebenzisa inqubo yokubumba umjovo.Lokhu kuhlanganisa ukuncibilika kwepulasitiki emshinini womjovo bese uwujova endaweni evalekile, lapho upholisa khona futhi uqine ukuze uthathe isimo esifunekayo.

Ezinye izinqubo ongazisebenzisa zifaka ukubumba kokucindezela, i-vacuum cast, noma ukuphrinta kwe-3D.Indlela ngayinye inikeza izinzuzo eziyingqayizivele kanye nokubi kuye ngokuthi hlobo luni lwengxenye ozama ukuyidala.

Ngazo zonke izindlela, ukuthola izinga lokushisa elifanele nokucindezela kuyisihluthulelo sokufinyelela ubukhulu obunembile kanye nezakhiwo zezinto ezifiselekayo.

Imishini yezingxenye ze-silicon

Kunezimboni eziningi ezingasebenzisa izingxenye ezithambile ze-silicon njenge-Automotive, Medical, Electronic, houseware, kitchenware, nezinye eziningi.Ezingxenyeni, ngokuvamile ungathola lokhu okufana nama-Gaskets, Seals, O-rings, Air filters, Hoses, Izingxenye zokukhanyisa, amakesi omakhalekhukhwini, amakhava ekhibhodi, Izintambo kanye nokufakwa kwezintambo kanye nemishini eminingi Yezokwelapha.

Izingxenye zokugxiviza zensimbi ziyizingxenye zensimbi ezidalwe ngenqubo yokugxiviza kwensimbi, indlela yokukhiqiza ehlanganisa ukubhoboza, ukusika, noma ukwenza amashidi ensimbi abe yizimo ezifunwayo.

I-Metal stamping isetshenziselwa ukwakha izingxenye zezimboni ezihlukahlukene ezihlanganisa izimboni zezimoto kanye ne-aerospace.

Ingase futhi isetshenziselwe ukudala izimo ezijwayelekile neziyinkimbinkimbi.Izinzuzo zokusebenzisa isitembu sensimbi zihlanganisa ukusebenza kahle kwezindleko, ubunkimbinkimbi bomklamo kanye nokuguquguquka.

I-SPM isize amakhasimende ezimpahleni eziningi zokugxiviza zensimbi zephrojekthi yawo ye-turnkey, isevisi yethu esebenzayo yobunjiniyela ingonga izindleko zabo eziningi nesikhathi.

I-Jig ne-fixtures angamathuluzi asetshenziselwa ukusiza ekukhiqizeni izingxenye nezingxenye ezihlukahlukene.

I-jig iyithuluzi elikhethekile elisiza ukuqondisa, ukubamba, noma ukubeka ucezu lomsebenzi endaweni ngesikhathi semisebenzi ehlukene yokumaka, njengokumba, ukugaya, nokubumba.

Izinto ezilungiswayo ngamadivayisi anamathiselwe emshinini noma ebhentshini lokusebenza futhi asiza ukuthola nokuvikela izingxenye ngenkathi kusetshenzwa.

Zingenziwa ngokwezifiso ukuze zivumelane nemisebenzi ehlukahlukene ukuze kuqinisekiswe ukunemba nokusebenza kahle.Kokubili ama-jigs kanye nezinto ezilungiswayo zingenziwa ngensimbi njengensimbi noma i-aluminium futhi zibalulekile ekukhiqizeni izingxenye ezinembile ngomzamo omncane.

I-SPM yenza amajigi nezinto ezilungiswayo zokukhiqiza ukubumba komjovo wethu futhi futhi ihlinzeka ngenkonzo yokuyenza kumakhasimende.

Uma unesidingo salokhu, sicela uxhumane noma nini.

THOLA I-QUOTE ESHESHAYO MANJE!

-

Umjovo wesikhunta somgodi omningi wamakepisi ephakethe...

-

Plastic tooling umndeni isikhunta sezimoto umsila lig...

-

CNC milling kanye turning abathengisi machining

-

Umkhiqizi wesikhunta somjovo wepulasitiki, i-die castin...

-

Isevisi yokubumba yomjovo wePlastiki eyenziwe ngokwezifiso

-

Isikhunta sokujova epulasitiki esinembayo somthengi ...