| Umshini kanye Nohlobo | Izingxenye zokunemba ze-elekthronikhi ezenziwe ngesikhunta sokujova ipulasitiki ye-multi cavity, | |||||

| Ingxenye yegama | Isixhumi seselula | |||||

| I-Resin | Izinto ze-powder metallurgy | |||||

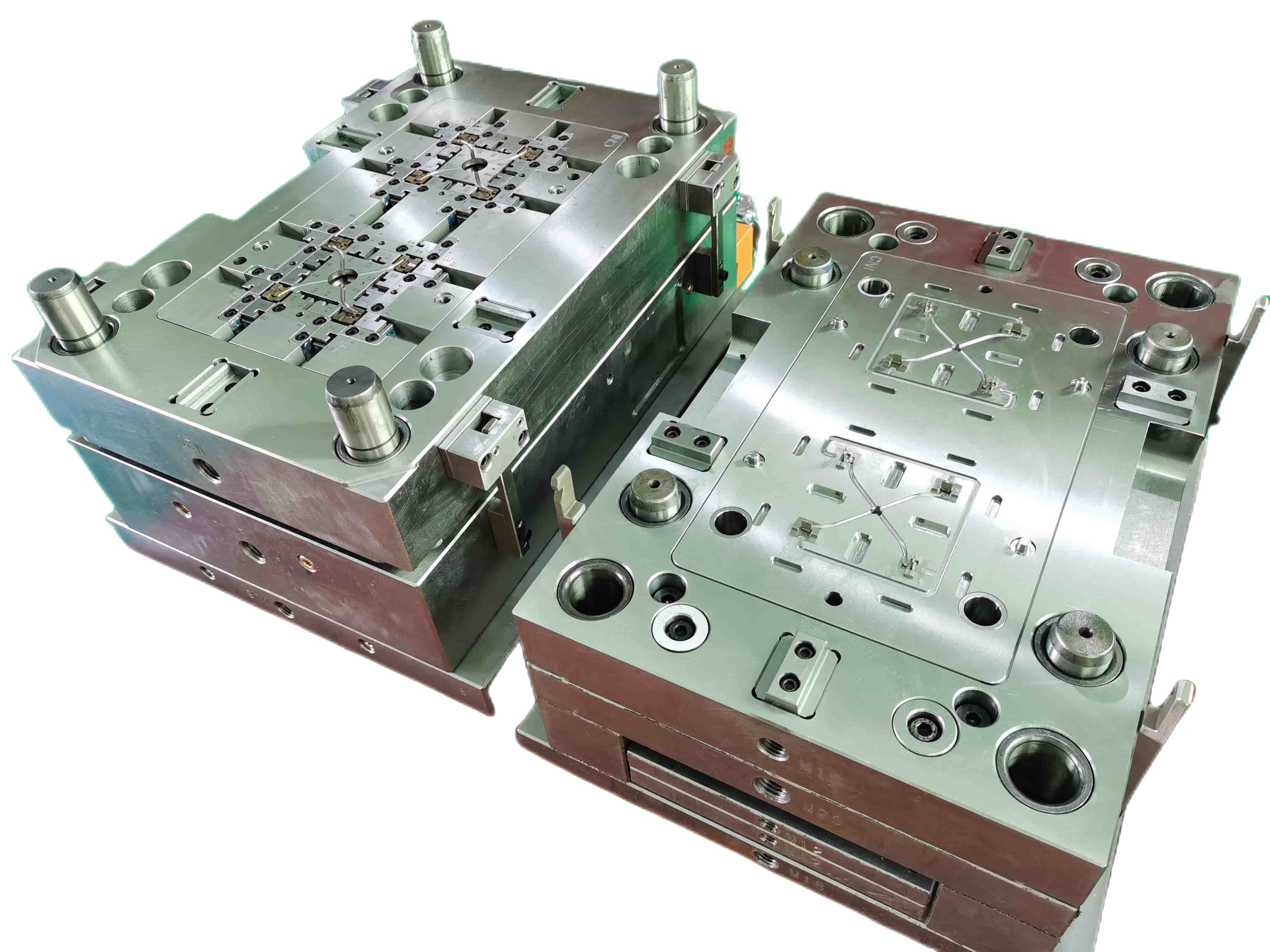

| Cha | 1*8 | |||||

| Isikhunta Isisekelo | I-S50C | |||||

| Insimbi ye-cavity&Core | I-S136 HRC 52-54 | |||||

| Isisindo sethuluzi | 450KG | |||||

| Usayizi wethuluzi | 450X350X370mm | |||||

| Cindezela i-Ton | 90T | |||||

| Impilo yesikhunta | 1000000 izithombe | |||||

| Uhlelo lomjovo | Umgijimi oshisayo, 2pcs Mold-master amathiphu ashisayo | |||||

| Isistimu yokupholisa | Ukupholisa ngamafutha, izinga lokushisa lesikhunta liyi-120 degree | |||||

| Uhlelo Lokukhipha | Ukukhishwa kwezinyathelo ezimbili | |||||

| Amaphuzu akhethekile | Izinto ze-powder metallurgy, isikhunta sokujova ngokunemba, umgijimi oshisayo, isikhunta esingu-8, isikhathi somjikelezo omfushane | |||||

| Ubunzima | Ukubekezelela ukunemba okuphezulu, isikhunta sokushisa okuphezulu, isikhunta esifushane esenza isikhathi sokuhola kanye nesikhathi esifushane kakhulu somjikelezo wokubumba.Izinto ezibonakalayo ziyi-Powder metallurgy material enesikhathi esifushane sokupholisa kanye nesidingo esikhulu semishini yokujova. | |||||

| Isikhathi esiholayo | 4 amasonto | |||||

| Iphakheji | Isikhunta sihlala eChina sokukhiqiza ukubumba ipulasitiki | |||||

| Ukupakisha izinto | Ukuqinisekiswa kwensimbi, idizayini yokugcina yethuluzi le-2D ne-3D, idokhumenti yomgijimi oshisayo, izingxenye eziyisipele nama-electrode... | |||||

| Ukuncipha | 1.005 | |||||

| Ukuqedwa kobuso | I-SPI B-1 | |||||

| Isikhathi somjikelezo wokubumba umjovo | 9 imizuzwana | |||||

| Ukwelashwa kwesibili kwemikhiqizo ngemuva kokubunjwa | Ukwelashwa kokushisa kwemikhiqizo ebunjiwe | |||||

| Thumela ku | Isikhunta sihlala eChina sokukhiqiza ukubumba ipulasitiki | |||||

Ubunzima

Ukubekezelela ukunemba okuphezulu, isikhunta sokushisa okuphezulu, isikhunta esifushane esenza isikhathi sokuhola kanye nesikhathi esifushane kakhulu somjikelezo wokubumba.

Izinto ezibonakalayo ziyi-Powder metallurgy material enesikhathi esifushane sokupholisa kanye nesidingo esikhulu semishini yokujova.

Iyini i-powder metallurgy?

I-powder metallurgy iyinqubo yokukhiqiza esebenzisa ukuhlanganisa okucindezelwe kanye nokucwiliswa kwezinhlayiya zensimbi ukuze kwakhiwe izingxenye nezingxenye ezihlukahlukene.Inqubo ihilela ukuhlanganisa ndawonye izinsimbi eziyimpuphu njengensimbi, i-aluminium, ithusi, insimbi engagqwali ne-cobalt nezithambisi nama-agent abophayo ngaphambi kokuzifaka emazingeni aphezulu okucindezela.Ingxube ewumphumela ibe isishisiswe kuze kube yilapho izinto zihlangana ndawonye ngamakhemikhali, zenze izingxenye eziqine kakhulu kunezinsimbi zendabuko noma ezenziwe ngomshini.

Ngenxa yokuguquguquka kwayo, i-powder metallurgy iye yanda kakhulu ekukhiqizeni izingxenye eziyinkimbinkimbi ezisetshenziselwa izimoto, i-aerospace kanye nezinhlelo zokusebenza ze-electronic zabathengi.

Kuyini isikhunta sokushisa okuphezulu?

Ukubumba okunokushisa okuphezulu kuwuhlobo lwenqubo yokubumba umjovo esebenzisa amazinga okushisa aphakeme nezingcindezi ukukhiqiza izingxenye ezinamandla amakhulu nokuqina.Inqubo isebenza ngokushisisa impahla eluhlaza ye-thermoplastic ize incibilike bese ijova esikhunjeni esivalekile lapho igcinwa khona ngaphansi kwengcindezi.Ukushisa okuvela kunhlaka encibilikisiwe kuhlanganiswe nokucindezela kubangela ukuthi into yakheke ibe yisimo esifunekayo ngaphambi kokupholisa.Le nqubo ivumela ukwakhiwa kwezingxenye eziyinkimbinkimbi ezimelana nezinga lokushisa elidlulele kanye namakhemikhali abolayo, okuzenza zilungele ukusetshenziswa ezimbonini ezinjengezezimoto, i-aerospace, imishini yezokwelapha kanye ne-electronics.

I-Common Plastic Material ihlanganisa: I-PEEK, i-PPSU, i-ULTEM® (i-Polyetherimide, i-PEI), i-Celazole®, i-Vespel®, i-Torlon® (i-Polyamide-imide) njalonjalo.

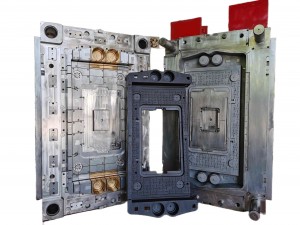

Isikhunta design for high lokushisa isikhunta

Lapho uklama isikhunta samapulasitiki asezingeni eliphezulu kubalulekile ukufaka amashaneli okudlulisa ukushisa kanye nokusebenzisa izikhonkwane ezishisayo ukuze uqinisekise ukuthi ipulasitiki iphola ngokulinganayo ngesikhathi sokubumba umjovo.

Ukwengeza, ukukhetha isikhunta esifanele kubalulekile ekudaleni izingxenye ezingamelana namazinga okushisa aphezulu ngaphandle kokungqubuzana noma ukuqhekeka.

Kule phrojekthi, sisebenzise insimbi ye-S136 nge-HRC 52 ~ 54, umthamo wokukhiqiza uphezulu kakhulu, izingxenye ze-100000pcs zazidingeka usuku ngalunye, ngakho-ke sasebenzisa isikhunta esingu-8 se-cavity futhi senza amakhophi amaningi ukuhlangabezana nesicelo sobuningi.Ukupholisa, kupholiswe ngamafutha futhi izinga lokushisa lesikhunta lifinyelela ku-120 degree.Isikhathi somjikelezo amasekhondi angu-9 futhi sisebenzise isinyathelo esi-2 sokukhipha izingxenye zokukhishwa.Le ngxenye izophathwa ngokushisa ngemva kokubunjwa.

Ithuluzi lesikhunta lomjovo yisikhunta esingu-8 sokushisa okuphezulu komjovo.

Ipulasitiki iyimpuphu yensimbi futhi izingxenye ezibunjiwe zizodinga ukwelashwa ngokushisa njengoba kuyisixhumi esihambayo.

Isikhathi somjikelezo wokubumba umjovo sifushane kakhulu, imizuzwana eyi-9 ngokudubula okukodwa.

Senze amathuluzi amaningi wokukopisha kuleli khasimende.Abaklami bethu basebenza ngempumelelo kakhulu, ku-DFM, iqedwa osukwini olungu-1, ukwakheka kwe-2D phakathi kwezinsuku ezi-2, kanye ne-3D phakathi nezinsuku ezi-3.

Isikhathi sokuhola sokukhiqiza isikhunta singamaviki ama-4.

Ngokwakhiwa kwesikhunta, uma isikhathi siphuthuma kakhulu, ngokuvamile senza umdwebo we-3D ngokuqondile ngemva kwe-DFM, kodwa-ke, kufanele usekelwe ekugunyazweni kwamakhasimende.

Isakhiwo se-2D

3D isikhunta design

3D isikhunta design

FAQ

Ibhizinisi lethu elikhulu elokwenza isikhunta somjovo wepulasitiki, ukwenza isikhunta se-die cast, ukubumba umjovo wepulasitiki, i-die casting (i-Aluminium), ukunemba kwemishini kanye nokwenza i-prototyping ngokushesha.Siphinde futhi sinikeze ngemikhiqizo engeza inani elihlanganisa izingxenye ze-silicon, izingxenye zokugxiviza zensimbi, izingxenye ze-extrusion kanye nebala

Cha, siyimboni yangempela yokukhiqiza isikhunta kanye nemboni yokubumba umjovo wepulasitiki.Singakunikeza isithombe sokubhalisa ukuze sisetshenziswe kanye nanoma yiluphi olunye ulwazi olufunayo uma ludingeka.Okwamanje, ungasivakashela noma nini, ngisho kungabikho ama-aphoyintimenti.

Ithimba le-Suntime linikeza isitayela sokusebenza sesevisi engu-24/7.Ngamaholide omphakathi aseShayina, ukuthengisa kwethu nonjiniyela bangathatha umsebenzi wesikhathi esengeziwe kunoma yisiphi isimo sakho esiphuthumayo.Futhi uma kunesidingo, sizokwenza konke okusemandleni ukucela abasebenzi ukuthi bathathe umsebenzi wesikhathi esengeziwe ngamaholide emini kanye namashifu ebusuku ukuze bahlangabezane nezidingo zakho eziphuthumayo.

Sinesipiliyoni esingaphezu kweminyaka eyishumi yokuthumela emakethe yomhlaba wonke, isikhunta somjovo wepulasitiki esithekelisa ngaphandle, isikhunta se-die cast, izingxenye zokuphonsa izinsimbi, imikhiqizo ebunjiwe yomjovo wepulasitiki kanye nezingxenye zemishini ye-CNC njll.

Ukukhiqiza isikhunta, sine-CNC, EDM, imishini yokugaya, imishini yokugaya, imishini yokumba, njll,.Ukubumba ipulasitiki yangokwezifiso, sinemishini yomjovo emi-4 ukusuka kumathani angama-90 kuye kwangama-400.Ukuhlola izinga, sinehexagon CMM, Projector, hardness tester, height gauge, vernier caliper nokunye.

THOLA I-DFM YAMAHHALA NAMUHLA!

-

Iphrojekthi yokubumba umjovo wePlastiki kusuka ku-Rapid p...

-

Isikhunta esikhulu somjovo wepulasitiki wezimoto...

-

Plastic tooling umndeni isikhunta sezimoto umsila lig...

-

Umjovo wesikhunta somgodi omningi wamakepisi ephakethe...

-

Faka isikhunta sepulasitiki somjovo we-Automo...

-

High glass fiber Nylon impahla isikhunta amathuluzi for ...