Lawa amaphuzu angu-3 okushisa okuphezulu kwesikhunta nge-PPSU resin

Yiziphi izinzuzo zezinto ze-PPSU?

Ukumelana nokushisa kwesikhathi esifushane kwepulasitiki ye-PPSU kuphakeme ngama-degree angu-220, futhi izinga lokushisa lesikhathi eside lingafinyelela ama-degree angu-180, futhi lingakwazi ukumelana nemvelo yokushisa kawoyela ye-170-180 degrees.Izingxenye ze-PPSU zinokuzinza okuhle kwe-dimensional, futhi zingakwazi ukumelana namanzi ashisayo/isiqandisi/uwoyela wesibaseli.Ngalesi sakhiwo esihle kakhulu, i-PPSU ingasetshenziswa ukukhiqiza imikhiqizo esezingeni eliphakeme yezobuchwepheshe kanye nemithwalo ephezulu.Manje isiba yimpahla yokuqala yokushintsha izinsimbi, izitsha zobumba kanye nama-polymer aqinile.

Amapulasitiki e-PPSU asesetshenziswa ngokwandayo ekulungiseleleni nasekushiseleni kabusha ukudla okushisayo, ikakhulukazi ezingxenyeni zamandla kagesi aphezulu okumele zibe nokuzinza okuphezulu kwe-dimensional kanye nezakhiwo ezinhle zokufakwa kwemishini kagesi kanye nokumelana nokuguga okuphezulu, ukumelana nomlilo okuhle kakhulu, nokumelana kahle nokugqwala kwamakhemikhali. kanye ne-hydrolysis.

Ngalokhu, iba yinto ebalulekile ezinhlobonhlobo zezicelo ezimbonini ezifana ne-aerospace, izinto zikagesi neze-elekthronikhi, ezezimoto nezokuthutha.

Ungawenza kanjani ukulawulwa kwezinga lokushisa kokubunjwa kwe-PPSU?

Njengamanye ama-thermoplastics wobunjiniyela, ukukhiqizwa okuzinzile kwezingxenye ezibunjiwe zekhwalithi ephezulu kudinga ukulawulwa okunembile kwezinga lokushisa lesikhunta sokujova izinga lokushisa eliphezulu.Kokubili amanzi namafutha angakwazi ukulawula ngokuzinzile izinga lokushisa lesikhunta phakathi kuka-140 no-190 degrees.Uma imishini yokulawula izinga lokushisa iklanywe kahle, amanzi angaba ngu-200 degrees angasetshenziswa njengemidiya yokulawula izinga lokushisa.Ukulawula izinga lokushisa nge-elekthronikhi kungasetshenziswa ezimweni ezithile.Ngaphambi kokubunjwa komjovo, Izinto ze-PPSU kufanele zomiswe, siphakamisa ukuthi zomiswe izinto ngezinga lokushisa elingu-150-160 degrees amahora angu-3-6.Umgqomo womshini wokubumba umjovo kufanele uhlanzwe ngokwanele.Futhi izinga lokushisa lomjovo linconywa ukuthi lilawulwe cishe ngama-360-390 degrees.

Ungazenza kanjani isikhunta sokujova okushisa okuphezulu kwempahla ye-PPSU?

Isikhunta sokujova se-PPSU impahla kumele sikwazi ukumelana namazinga okushisa aphakeme njengethuluzi lokubumba izinga lokushisa eliphezulu.Ngaphezu kokwamukela idizayini yemishini enengqondo nokukhetha izinto zokubunjwa ezifanele, amapayipi amelana nokushisa namelana nokucindezela kufanele futhi asetshenziselwe ukuthuthukisa idizayini yamashaneli okupholisa, ama-seal, nezixhumi.

Amaphuzu Wokuklama:

1. Ukukhethwa nokwelashwa kwensimbi: a).Ukushisa kwesikhunta kufanele kusekelwe ku-140 kuya ku-150 degrees, futhi impilo yesikhunta kufanele ibhekwe ekukhiqizeni okuningi.b).Ukwelashwa kokushisa kwesikhunta kuyadingeka ukuze kube yi-HRC60-65 iyonke.c).Ukwelashwa kwe-electroplating kungandisa impilo yesevisi yokubumba.

2. Ukuma komgijimi: nxazonke noma i-trapezoid ifanelekile.Umthombo we-slug obandayo nawo uyadingeka.

3. Izinhlobo zesango: Isango lephoyinti lokuphina, isango lethebhu, isango lediski, isango elikhuluma, isango elisemaceleni, isango eliqondile kanye nesango elincane.

4. Ukungenisa umoya ngegesi: Ukungenisa umoya kubaluleke kakhulu esikhunjeni se-PPSU sempahla.Ukungangenisi umoya okwanele kuzodala ukushiswa, ukushintsha kombala kanye nendawo emangelengele nokunye.Isikhala segesi sivamise ukuba ngu-0.015~0.2mm ubude futhi sibe ngaphezu kuka-2mm ububanzi.

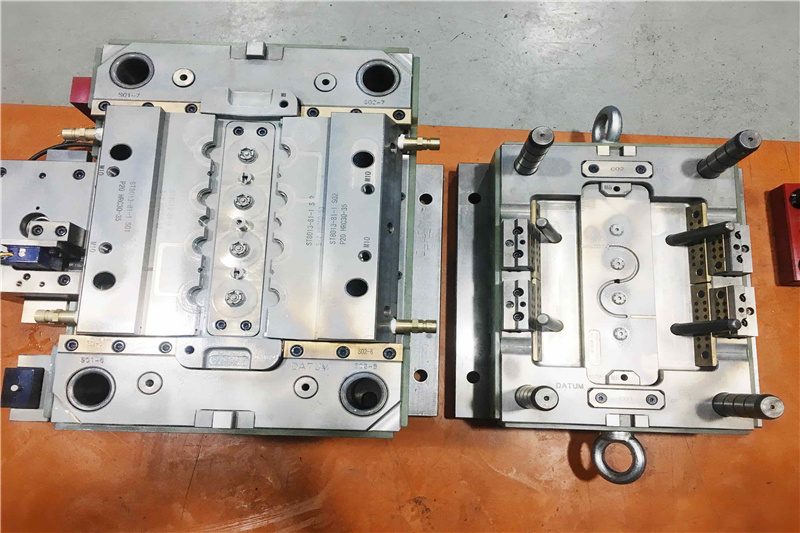

I-Suntime Precision Mold inolwazi olucebile lokwenza isikhunta somjovo wepulasitiki wokushisa okuphezulu kwesikhunta sezinto ezifana ne-PPSU ne-PEEK.Amakhasimende ajabule kakhulu ngekhwalithi yethu ephezulu nesikhathi sokuhola esisheshayo.Ngezansi kwesithombe esinye sesikhunta sokushisa okuphezulu esisenzele i-pluping & izingxenye ezifanelekile.Kuyisikhunta esingu-4 esizikhulula ngokuzenzakalelayo.Ukuze uthole ulwazi olwengeziwe mayelana nalolu hlobo lwesikhunta, sicela uhlole udaba lwethu kuwebhusayithi:https://www.suntimemould.com/auto-unscrewing-plastic-injection-mould-with-ppsu-material-high-temperature-mold-product/

Isikhathi sokuthumela: Dec-18-2021