Izinto ofuna ukuzazi mayelana nesikhunta sokujova

Ukwakhiwa kwesikhunta esihle kuyisiqalo esibalulekile.Ngengxenye yakho yemidwebo (2d/3d), abaklami bethu nonjiniyela bazoba nomhlangano wokudingida isakhiwo sengxenye, ubunzima, izicelo zamakhasimende kanye nomqondo wokuklanywa kwesikhunta kuso.

1. I-DFM: bonisa umqondo wesakhiwo sesikhunta, ukupholisa, isistimu yomjovo, isistimu yokukhipha, ukushuba kodonga, i-angle yokusalungiswa, ukuqoshwa, ukuqedwa kwendawo, imodi yokwehluleka kokuklama kanye nokuhlaziywa kwemiphumela kanye nezinye izindaba zokukhishwa kwesikhunta.

2. Ukugeleza kwesikhunta (kunikeza phakathi kwezinsuku ezi-1~3)

3. Idizayini yesakhiwo se-Mold 2D (ukunikezwa phakathi kwezinsuku ezi-2~4)

4. Idizayini ye-Mold 3D (isofthiwe: UG, inikezwa phakathi kwezinsuku ezingu-2~5)

Iyini isikhunta esihle?Kumelwe ibe nekhwalithi enhle ukuhlangabezana nezicelo zokukhiqiza izinzile futhi ngokushelela, futhi asikho isidingo sokuchitha isikhathi esiningi nezindleko zokunakekelwa nokulungiswa.

I-Suntime inabaklami abangu-6 sebebonke abanolwazi lweminyaka engaphezu kwengu-5-10, bahlala benaka ngokukhethekile ukucaciswa kwamakhasimende kanye nemininingwane ngokucabanga ngesixazululo sokonga esisekelwe kukhwalithi ezinzile nenhle.Ulwazi lwabo lweminyaka lokuthumela isikhunta kwamanye amazwe lubanika ulwazi olukhulu ngamazinga omhlaba jikelele kanye nezidingo zekhwalithi.

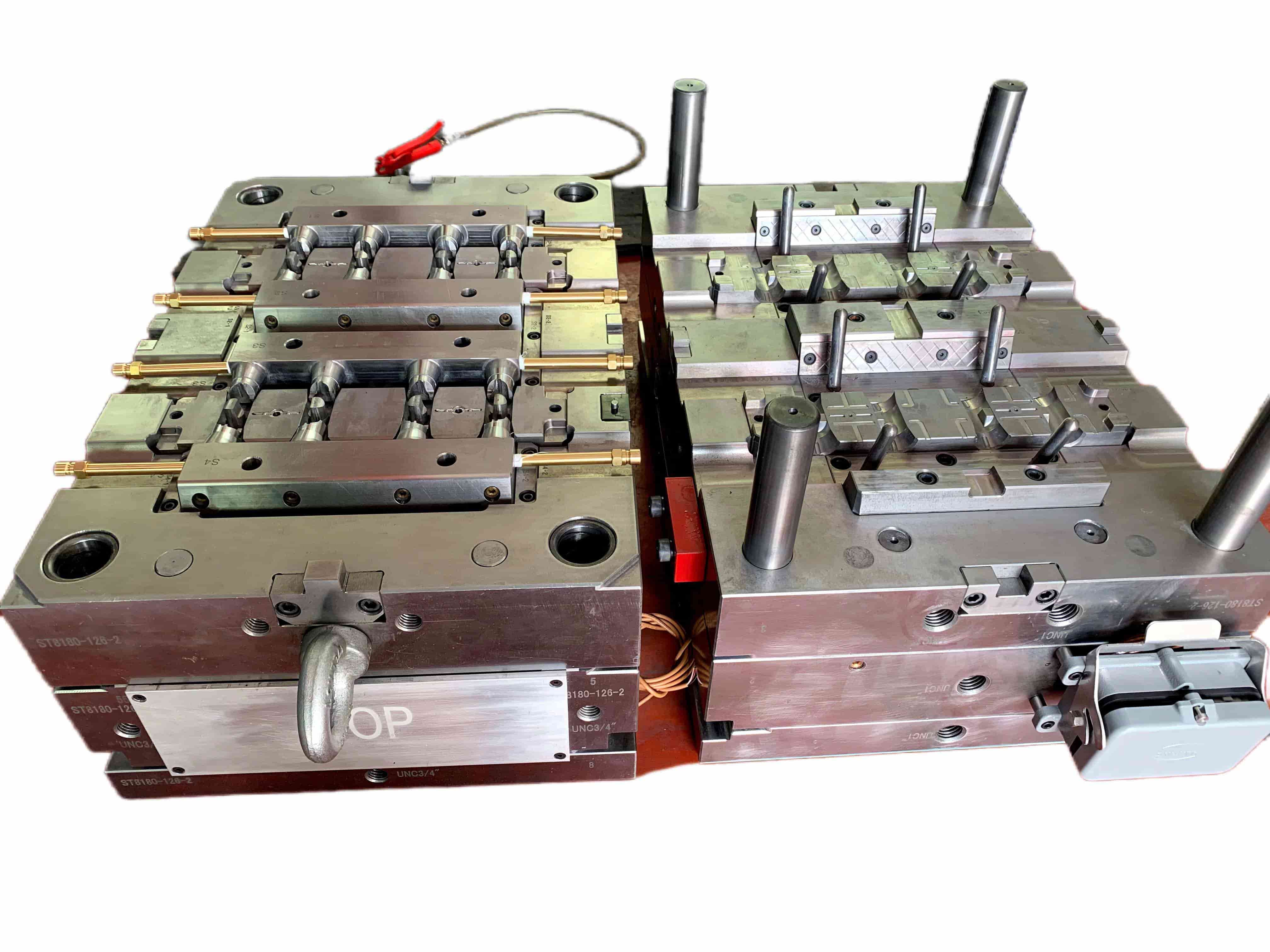

Ireferensi yedizayini yesikhunta sekhava yokukhanyisa kwezimoto

Umenzi wesikhunta womjovo wepulasitiki angasiza amakhasimende ngezindlela ezihlukahlukene.Singakha izingxenye zepulasitiki ezenziwe ngokwezifiso ezihlangabezana nokucaciswa kwazo kanye nezimfuno zazo.Singahlinzeka ngezinsizakalo zokuklama nezobunjiniyela ukuze siqinisekise ukuthi umkhiqizo wokugcina uhlangabezana nezidingo eziqondile zekhasimende.Futhi sihlinzeka ngemva kwesevisi efana nokugcinwa nokulungiswa kwezibunjwa ezikhona ze-plastic injection ukuze zihlale zisebenza kahle noma ngabe efektri yethu noma enkampanini yamakhasimende.

Njengokwenza amathuluzi wokubumba umjovo, singakwenzela lokhu ngezansi:

1. Ukwesekwa kwangaphambi kokuthengisa kubandakanya kodwa akukhawulelwe ekunikezeni amakhotheshini asheshayo, umxhumanisi wezinketho zezinto ezibonakalayo, ukuhlaziya amathuluzi we-DFM nokunye.

2. Idizayini yesikhunta esivela ku-DFM, ukugeleza kwesikhunta, ukwakheka kwesakhiwo se-2D kanye nomklamo wesikhunta we-3D.(zingakapheli izinsuku ezi-2 ~ 4 zokusebenza)

3. Ukwenziwa kwesikhunta ngokwezifiso sePlastiki ne-Aluminium.

4. Isevisi yobunjiniyela yokulandela iphrojekthi kanye nomunye umsebenzi ohlobene njengokukhishwa kwemisebenzi

5. Ukuhlolwa kwesikhunta kanye nokukhiqizwa kokubunjwa komjovo wevolumu ephansi ngaphambi kokuthunyelwa kwesikhunta

6. Ukuguqulwa kwesikhunta / ukulungiswa ngokushesha

7. Ukuthuthwa kwemikhumbi ngendiza, ulwandle noma isitimela.

Yini esiyenzela ukuphathwa kwephrojekthi yakho (ukugeleza komsebenzi)?

Isinyathelo 1:Ngomdwebo wezingxenye zamakhasimende (i-2D&3D) kanye nokucaciswa, sibamba imihlangano yokuqala nabaklami, onjiniyela kanye nomphathi wokusebenza ndawonye ukuze sifunde imininingwane futhi senze imemo yamaphrojekthi.

Isinyathelo sesi-2:Ngemva kokugunyazwa kwamakhasimende kwe-DFM, aqala isakhiwo se-2D nomdwebo wesikhunta se-3D nokuhlaziywa kokugeleza kwe-Mold ngesikhathi esifushane.

Isinyathelo sesi-3:Phakathi nayo yonke le nqubo, umbiko wamasonto onke uzonikezwa njalo ngoMsombuluko ukuze kuqinisekiswe ukuthi amakhasimende aphethe zonke izinto.

Isinyathelo sesi-4:Ngokuhlolwa kwesikhunta, sithumela umbiko wesilingo onezithombe zesikhunta, amasampula ezithombe, isithombe esifushane, isithombe sesisindo, izinkinga zokubumba kanye nezixazululo zethu.

Ngaleso sikhathi, ividiyo ye-Molding, umbiko wokuhlola kanye nepharamitha yokubumba izonikezwa ngokushesha ngangokunokwenzeka ngemva kwalokho.

Isinyathelo sesi-5:Ngemvume yamakhasimende yokuthumela amasampula, sithumela izingxenye nge-express ngaphansi kwe-akhawunti ye-Suntime.

Isinyathelo sesi-6:Ukulungiswa kwesikhunta noma ukuguqulwa kuzoqalwa ngesikhathi esisodwa ngemva kokuxhumana namakhasimende.

Isinyathelo sesi-7:Isikhunta singathunyelwa ngemvume yamakhasimende.Kudingeka isikhunta esingaphezu kuka-50% ukuze sithunyelwe ngemva kwe-T1.

Isinyathelo sesi-8:Iphakheji yokuthumela ehlanganisa: i-memory stick enomklamo wokugcina wesikhunta we-2D&3D, i-BOM, izitifiketi zempahla, izithombe nezinye izingxenye eziyisipele.

Isinyathelo 9:Hlanza isikhunta futhi uhlole kabili ngohlu lokuhlola lwe-QC ngaphambi kokupakisha.

Isinyathelo 10:Ukupakisha i-vacuum yokuhamba.

Isinyathelo 11:Amadokhumenti nokwesekwa kokuthengisa ukuze kugunyazwe ngokwezifiso.

Ikhotheshini izonikezwa emahoreni angama-24 kusuka ku-SPM!

Sicela usithumele ingxenye yemidwebo ye-2D/3D ukuze uthole ikhotheshini esheshayo.

Uma ingekho imidwebo, sula izithombe ezibonisa ukwakheka nobukhulu, noma, amasampula embonini yethu ngokuqondile.

Ifomethi yefayela: Dwg, Dxf, Edrw, Step, Igs, X_T

Izinyathelo zenqubo yokukhiqiza isikhunta somjovo

Inqubo yokwenza isikhunta somjovo wepulasitiki ingahlukaniswa ibe yizinyathelo ezilandelayo:

Idizayini:Ukuhlaziywa kwe-DFM kokubumba.Dala imidwebo yesikhunta ye-2D&3D.

Ukwenza imishini:Sika insimbi futhi usebenzise imishini efana ne-CNC, i-EDM, i-lathe nezinye ukuze wenze umumo ngokusekelwe emidwebeni.

Ukuqina:Ukushisa phatha insimbi ukubenza bafinyelele ubulukhuni futhi bahlale isikhathi eside.

Ubuso:Ukupholisha kanye nokwenziwa ukuze kuhlangatshezwane nezicelo zezimonyo.

Ukuhlanganisa nokufakwa:Hlanganisa zonke izingxenye zesikhunta sokugcina bese wenza ukulingana.

Ukuhlolwa Kwesikhunta:Hlola ukuthi yonke into isebenza kahle ngemva kokuhlanganisa.

Ukuhlola:Ngezingxenye ezibunjiwe, yenza ukuhlolwa kwesikhunta namasampula nge-CMM, iphrojektha, njll.

Ukulungisa/ ukuguqulwa:Ngokuya ngamasampula, yenza izilungiso noma izinguquko ezidingwa amakhasimende.

Thumela isikhunta ngemva kokuvunyelwa amakhasimende.

Indlela yokulondoloza izindleko zokwenza isikhunta sokujova?

Indlela yokulondoloza izindleko zokwenza isikhunta?Okokuqala, kufanele wazi inhloso yesikhunta.Uzoyisebenzisela ini?Ibuphi ubukhulu bento ofuna ukuyidala?Uthini umqulu wonyaka?Udinga izimbotshana ezingaki?Futhi ufuna ukunemba kangakanani?Zonke lezi zici zizothinta izindleko zesikhunta.

• Yenza umklamo ube lula ngangokunokwenzeka.Uma umklamo wengxenye uyinkimbinkimbi, isikhunta sizobiza kakhulu.Uma ungakwazi ukwenza umklamo ube lula, uzokonga imali.

• Sebenzisa izinto ezijwayelekile.Izindleko zokubumba umjovo zingancishiswa ngokusebenzisa izinto ezivamile esikhundleni sezinto ezingavamile.

• Sebenzisa i-geometry elula.I-geometry elula, isikhunta sizobiza kancane.

• Nciphisa inani lemigqa yokuhlukanisa.Imigqa yokuhlukanisa yilapho kuhlangana khona izingxenye ezimbili zesikhunta.Uma kukhona imigqa yokuhlukanisa, isikhunta sizobiza kakhulu.

• Nciphisa inani lama-cores kanye nezinto ezifakiwe.Ama-cores kanye nama-insert yizicucu ezisetshenziselwa ukudala izimbobo esikhunjeni.Lapho kukhona ama-cores amaningi kanye nokufaka, isikhunta sizobiza kakhulu.

• Sebenzisa inqubo yokukhiqiza evamile.Izindleko zokubumba umjovo zingancishiswa ngokusebenzisa inqubo yokukhiqiza evamile esikhundleni senqubo yangokwezifiso.

• Sebenzisa umklamo olula wesango.Isango yilapho impahla ingena khona emgodini wesikhunta ngesikhathi sokukhiqiza okubunjwe ngomjovo.Umklamo olula wesango uzonciphisa kokubili imfucuza yezinto ezibonakalayo kanye nesikhathi somjikelezo, okuzosindisa imali.

Uma unengxenye esandleni edinga ukwenza isikhunta somjovo, kodwa ungaqiniseki ukuthi zonga kanjani izindleko ngangokunokwenzeka, xhumana nathi, sizohlinzeka ngokuhlaziywa kwe-DFM mahhala futhi sikwazise imibono yethu.

FAQ

Ukwenziwa ngokwezifiso kwesikhunta somjovo wepulasitiki

Isikhunta se-aluminium die casting

Isikhunta esijwayelekile somjovo wepulasitiki

Multi-cavity umjovo isikhunta

Isikhunta somndeni

Isikhunta sezinhlelo zomgijimi oshisayo

Isikhunta sodaka

Phezu kwesikhunta

2K isikhunta

Isikhunta se-Thin Wall

Isikhunta se-prototyping esisheshayo

Ukugeleza Kwesikhunta: I-Mold FlowAnalysis

Ukumodela kwe-3D: I-Unigraphics, i-Pro/Engineer, i-Solidworks (amafayela: isinyathelo, i-Igs, i-XT, i-prt, i-sldprt.)

Umdwebo we-2D: I-Auto-CAD, i-E-drawing (amafayela: dwg,dxf,edrw)

Uhlobo Lwensimbi: GROEDITZ/LKM/ASSAB/DAIDO/FINKL...

Isikhunta Isisekelo: LKM,DME,HASCO,STEIHL....

Izingxenye Ezijwayelekile: DME, HASCO, LKM, Meusburger….

I-Hot Runner: I-Mold master, i-Mastertip, i-Masterflow, i-Husky, i-Hasco, i-DME, i-Yudo, i-Incoe, i-Syventive, i-Mold master...

Ukupholisha/Ukuthungwa: SPI,VDI, Mold-Tech, YS....Ukubumba

I-PEEK, PPSU,ABS, PC, PC+ABS, PMMA, PP, HIPS, PE(HDPE,MDPE,LDPE).PA12, PA66, PA66+GF,TPE,TPR,TPU, PPSU, LCP,POM,PVDF,PET,PBT, njll,.

I-A380, AL6061, AL5052, njll, .

Ukugeleza kwe-DFM/Isikhunta: 1~3 izinsuku zokusebenza

Idizayini ye-2D: 2 ~ 4 izinsuku zokusebenza

Idizayini ye-3D: 3 ~ 5 izinsuku zokusebenza

Isicaphuna kungakapheli amahora angama-24!

Ungaxhumana nathi ngama-imeyili, izingcingo,imihlangano yevidiyo,noma udinga ukuvakashelwa

Onjiniyela baxhumana ngqo ngesiNgisi

Isikhathi esiholayo sokukhiqiza isikhunta (kusukela ekuvunyweni kokuklama kuya ku-T1) amaviki angu-3 ~ 8 kuncike ebunzimeni besikhunta kanye nesakhiwo.

Kodwa kumaphrojekthi ajwayelekile, amaviki ama-4 ~ 5.

Yebo, sinesitifiketi se-ISO9001: 2015

Yebo, sinemishini yokubumba imijovo engu-7.

Amakhasimende ethu amakhulu atholakala eNyakatho Melika (USA, Canada), Europe (Germany, UK, Norway, Denmark, Portugal njalonjalo) nase-Australia.